Once the BMS is installed, you'll be tempted to take it for a spin right away, under a false sense of security because a BMS is present.

Resist the temptation! Test first!

All too often, expensive battery packs were damaged, some beyond repair, because incomplete systems have been operated before testing would reveal problems.

Just because a BMS is present, it doesn't mean it's wired and programmed correctly.

The BMS, by itself, cannot protect the pack.

The rest of the system must obey its command, otherwise there's nothing the BMS can do other than scream, while no one is listening.

Only after you have assured yourself that the entire system is protected, you may operate it normally and unsupervised.

Before operating a system:

- Test that the BMS is able to shut down charging

- Test that the BMS is able to shut down discharging

- Closely monitor the pack during its first charge cycle

- Closely monitor the pack during its first discharge cycle

The operation of the BMS within the overall system can be tested by forcing the outputs of the BMS controller.

The system must be configured so that the BMS can tell the charging sources (such as a charger or regen braking) to stop charging.

It can do so in one of 3 ways:

- The HLIM (High Limit) logic ouput, which is activated when charging must be stopped

- The CCL (Charge Current Limit) analog ouput, which goes down to 0 V when charging must be stopped

- The CCL value on the CAN bus, which goes down to 0 A when charging must be stopped

Procedure:

- Start charging the pack from the "Source" (such as a charger)

- Check that current is flowing into the battery

- On the terminal, do HOME / Test / Force Outputs / HLIM

- Press Y (or 1)

- Check that current is no longer flowing into the battery

- On the terminal, do HOME / Test / Force Outputs / HLIM

- Press N (or 0)

- Check that current is again flowing into the battery

- On the terminal, do HOME / Test / Release Outputs

If the "Load" can charge the pack (such as through Regen braking), repeat this test while charging from the Load

The system must be configured so that the BMS can tell the discharging sources (such as a motor driver or a V2G system) to stop discharging.

It can do so in one of 3 ways:

- The LLIM (Low Limit) logic ouput, which is activated when discharging must be stopped

- The DCL (Discharge Current Limit) analog ouput, which goes down to 0 V when discharging must be stopped

- The DCL value on the CAN bus, which goes down to 0 A when discharging must be stopped

Procedure:

- Start discharging the pack from the "Load" (such as a motor controller)

- Check that current is flowing out of the battery

- On the terminal, do HOME / Test / Force Outputs / LLIM

- Press Y (or 1)

- Check that current is no longer flowing out of the battery

- On the terminal, do HOME / Test / Force Outputs / LLIM

- Press N (or 0)

- Check that current is again flowing out of the battery

- On the terminal, do HOME / Test / Release Outputs

If the "Source" can discharge the pack (such as through V2G), repeat this test while discharging from the Source

Closely monitor the pack during its first charge cycle, to make sure the pack gets fully charged and it is not overcharged.

This is a tedious job, but far less of a hassle than having to rebuild the pack due to damage from overcharging.

Procedure:

- Start charging the pack from the "Source" (such as a charger)

- On the terminal, do HOME / Status / Pack

- Monitor the range of cell voltages, noting that the max never exceeds the Vmax setting

- Monitor the current, noting that its direction is "into battery"

- Once the pack is mostly charged, note that the number of "loads on" starts going up from 0

- Note that the current goes off when the "Avg cell Vtg, max" voltage reaches the Vmax setting, and comes back on when its voltage drops back down to the Vhigh setting

- Note that the cell voltages get closer to each other as the cells are being balanced

Closely monitor the pack during its first discharge cycle, to make sure the pack is not over-discharged.

This is a tediuos job, but far less of a hassle than having to rebuild the pack due to damage from over-discharging.

Procedure:

- Start discharging the pack into the "Load" (such as a motor controller)

- On the terminal, do HOME / Status / Pack

- Monitor the range of cell voltages, noting that the min never goes below the Vmin setting

- Monitor the current, noting that its direction is "out of battery"

- Note that the current goes off when the "Avg cell Vtg, min" voltage reaches the Vmin setting (and comes back on should that voltage go back up above the Vlow setting)

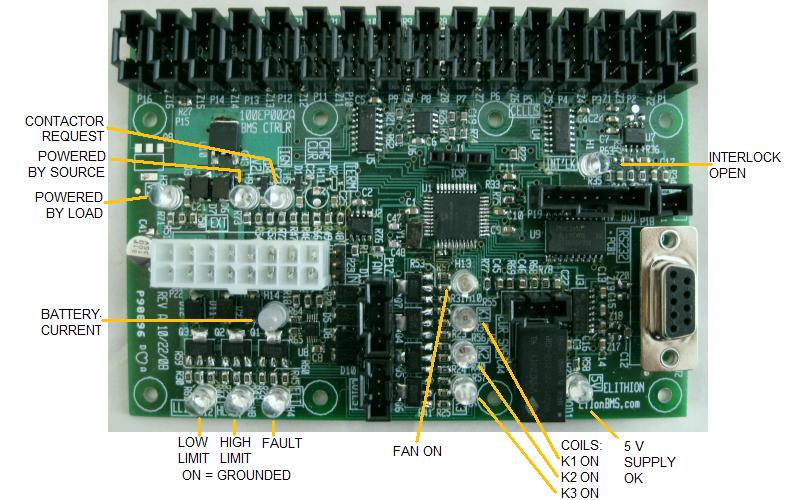

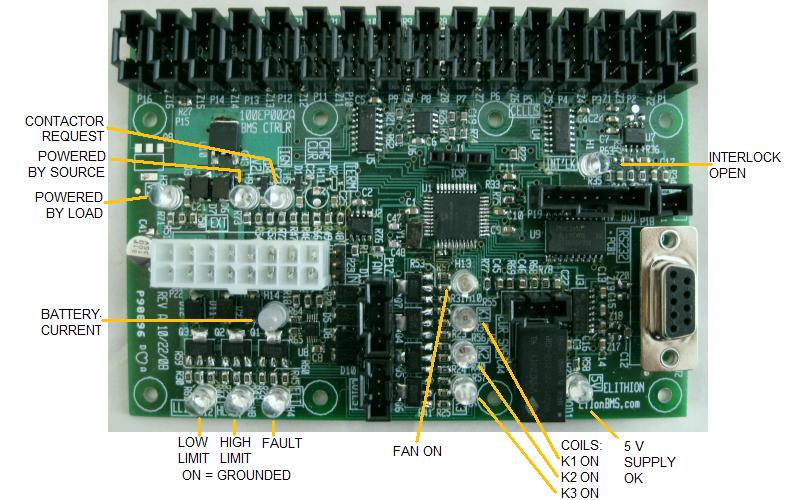

Function of LEDs, on a board level BMS controller.

The BMS controller has multiple LEDs to report its status.

| Name

| Color

| Function

|

| V+Load

| Red

| On if BMS is receiving power from the load (e.g.: motor controller)

|

| V+Source

| Amber

| On if BMS is receiving power from the source (e.g.: charger)

|

| ContReq

| Green

| On if BMS is receiving a request to turn on the contactors (e.g.: ignition line)

|

| Ibatt

| Red = discharging

Green = charging

| On if there's battery current; gets brighter with more current

|

| LLIM

| Blue

| On if BMS is driving the Low Limit line to ground

Note that polarity is programmable (ON = battery is fully discharged, or ON = battery is OK)

|

| HLIM

| Amber

| On if BMS is driving the High Limit line to ground

Note that polarity is programmable (ON = battery is fully charged, or ON = battery is OK)

|

| FLT

| Red

| On if BMS is driving the Fault line to ground

Note that polarity is programmable (ON = fault, or ON = OK)

|

| Fan

| Blue

| On if BMS is driving the Fan

|

| K1

| Amber

| On if BMS is driving the coil of precharge relay K1

|

| K2

| Red

| On if BMS is driving the coil of positive contactor K2

|

| K3

| Green

| On if BMS is driving the coil of negative contactor K3

|

| 5V

| Green

| On if the internal 5 V supply is OK

|

| I-lock

| Red

| On if the 2 pins of the Interlock connector are not shorted together

Note that polarity is programmable (shorted = OK, or open = OK)

|